Flexible/Semi-Flexible Materials

If you're looking for flexible or semi-flexible filaments, UltiMaker and Kimya both have great options.

TPU 95A (thermoplastic polyurethane) filament is the go-to choice for a wide array of manufacturing projects that demand the qualities of both rubber and plastic. Designed for 3D printing consistency, TPU 95A is a semi-flexible and chemical resistant filament with strong layer bonding. In addition, it is easier and faster to print than other TPU filaments.

Reasons to choose Ultimaker TPU 95A

- Exceptional wear and tear resistance

- High impact strength

- Shore-A hardness of 95

- Up to 580% elongation at break

- Good corrosion resistance to many common industrial oils and chemicals

- Engineered for a fast and seamless 3D printing experience

Ultimaker PP (polypropylene) is a favorite of engineers and manufacturers worldwide. It’s durable, tough, and offers exceptional fatigue resistance and low friction. It also has excellent chemical, temperature, and electrical resistance. Suitable for producing everything from electrical components to living hinges, PP is the go-to material for creating functional prototypes and end-use products. We recommend using Magigoo PP to ensure good bed adhesion when printing with this material.

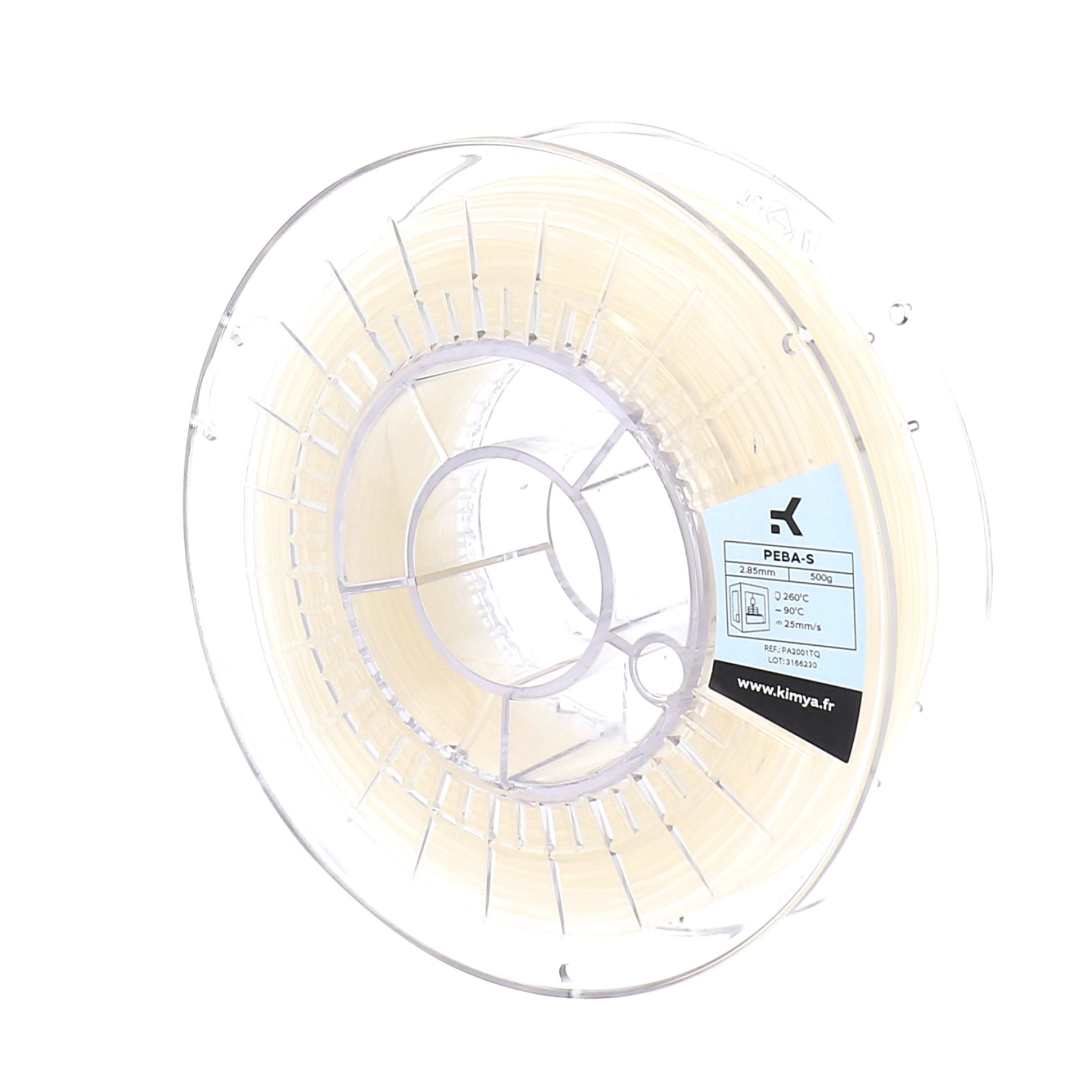

Kimya PEBA is extremely flexible and can handle up to 550% elongation without breaking. It is extremely impact resistant.